Introduction:

Diesel injection service is an important factor in determining a diesel engine’s fuel economy and emissions. The injection process affects the combustion efficiency and the fuel used, influencing the emissions produced.

Diesel engines have been used in various applications, including transportation, industrial, and power generation. They are popular for their high efficiency and durability, making them a popular choice for many industries. However, diesel engines also emit pollutants, such as nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC), which have adverse effects on human health and the environment. Therefore, it is useful to study the effect of the diesel injection service on fuel economy and emissions to develop cleaner and more efficient diesel engines.

Fuel injection:

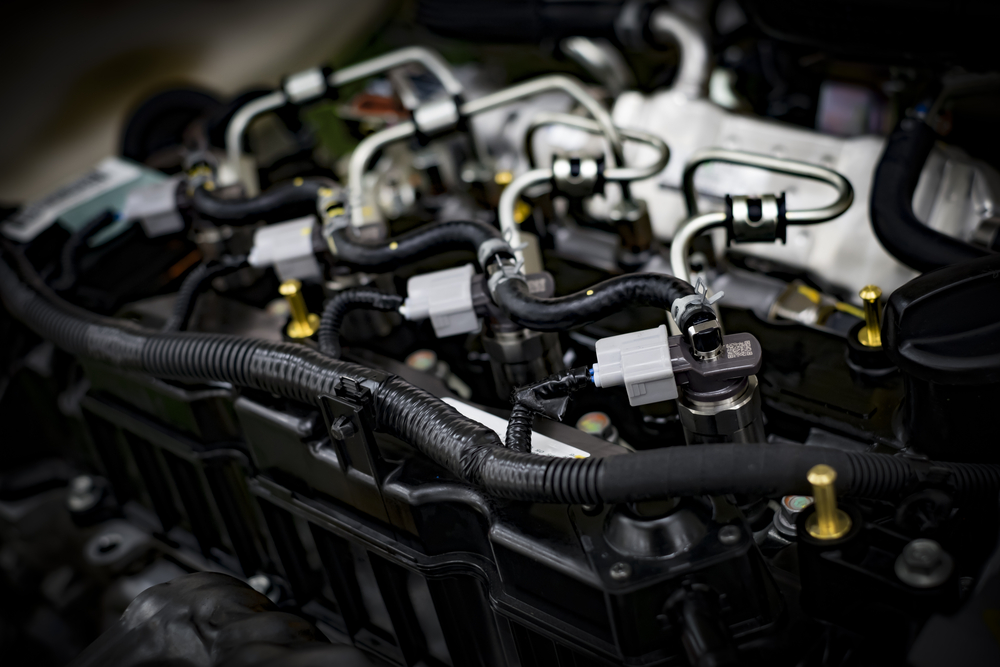

Fuel injection is a critical process in diesel engines, as it determines the fuel-air mixture and combustion characteristics. The fuel injection system comprises several components, including the fuel pump, injectors, fuel rail, and pressure regulator. The fuel pump pressurises the fuel and delivers it to the injectors, which spray it into the combustion chamber at high pressure and velocity. The fuel-air mixture ignites and combusts, generating power and emissions.

The injection timing, duration, and pressure significantly affect the fuel-air mixture and combustion characteristics. The injection timing refers to the moment when the injector starts spraying fuel into the combustion chamber relative to the piston position. The injection duration refers to the time during which the injector sprays fuel into the combustion chamber. The injection pressure refers to the pressure at which the fuel is delivered to the injectors.

Optimisation of Diesel Injection:

One way to optimise diesel injection is through the use of multiple injections. This involves splitting the main injection into two or more smaller injections, which can improve combustion efficiency and reduce emissions. The first injection can be used to initiate combustion, while the second injection can be used to complete the combustion process. This strategy can also be used to reduce noise and vibration, which are common issues in diesel engines.

Another way to optimise diesel injection is through the use of pilot injections. This involves injecting a small amount of fuel before the main injection, which can help to reduce ignition delay and improve combustion efficiency. Pilot injections can also be used to reduce emissions by promoting more complete combustion of the fuel.

Investigation on Effect of Diesel Injection:

Several studies have investigated the effect of diesel injection on fuel economy and emissions. One study investigated the effect of injection timing and pressure on the combustion and emissions of a diesel engine. They found that advancing the injection timing and increasing the injection pressure reduced the combustion duration, improved the fuel-air mixing, and reduced the emissions of NOx and PM. However, increasing the injection pressure beyond a certain level did not result in significant improvements and increased fuel consumption.

Another study by researchers at the University of Wisconsin-Madison investigated the effect of multiple injections on a diesel engine’s fuel economy and emissions. They found that using multiple injections improved combustion efficiency and lowered the emissions of NOx and PM. They also found that optimising the injection timing and duration for each injection further reduced fuel consumption and emissions.

Technologies to Improve the Fuel Economy and Emissions of Diesel Engines

Several technologies have been developed to improve diesel engine fuel economy and emissions. One of these technologies is common rail injection, which uses a high-pressure fuel rail to deliver fuel to the injectors. This technology allows for precise injection timing, duration, and pressure control, resulting in better fuel economy and emissions. Another technology is exhaust gas recirculation (EGR), which recirculates a portion of the exhaust gas back into the intake air to reduce the combustion temperature and emissions. EGR reduces the emissions of NOx but increases the emissions of PM and HC.

The effect of diesel injection on fuel economy and emissions is not straightforward, as it depends on several factors, such as the engine design, operating conditions, and fuel quality. Therefore, conducting experiments and simulations to optimise the injection parameters for each application is essential. Several simulation tools, such as GT-Power and AVL Boost, can simulate the combustion and emissions of diesel engines and predict the effect of injection parameters on fuel economy and emissions.

Conclusion:

In conclusion, diesel injection is crucial in determining diesel engines’ fuel economy and emissions. The injection timing, duration, and pressure significantly affect the fuel-air mixture and combustion characteristics. Advancing the injection timing and increasing the injection pressure can reduce the combustion duration, improve the fuel-air mixing, and reduce the emissions of NOx and PM. Using multiple injections and optimising the injection parameters further can reduce fuel consumption and emissions. Common rail injection and EGR can also improve diesel engine fuel economy and emissions. However, optimising the injection parameters for each application requires experimentation.