Introduction:

As the world turns towards sustainable energy solutions, wind power has emerged as a leading renewable energy source. To harness the full potential of wind energy, it is essential to optimize the efficiency and reliability of wind turbines. One crucial aspect in achieving this lies in the production of precision machined components specifically designed for wind turbines. In this article, we will explore the significance of precision machined components for wind energy and how they contribute to the overall performance of wind turbines.

What are Precision Machined Components?

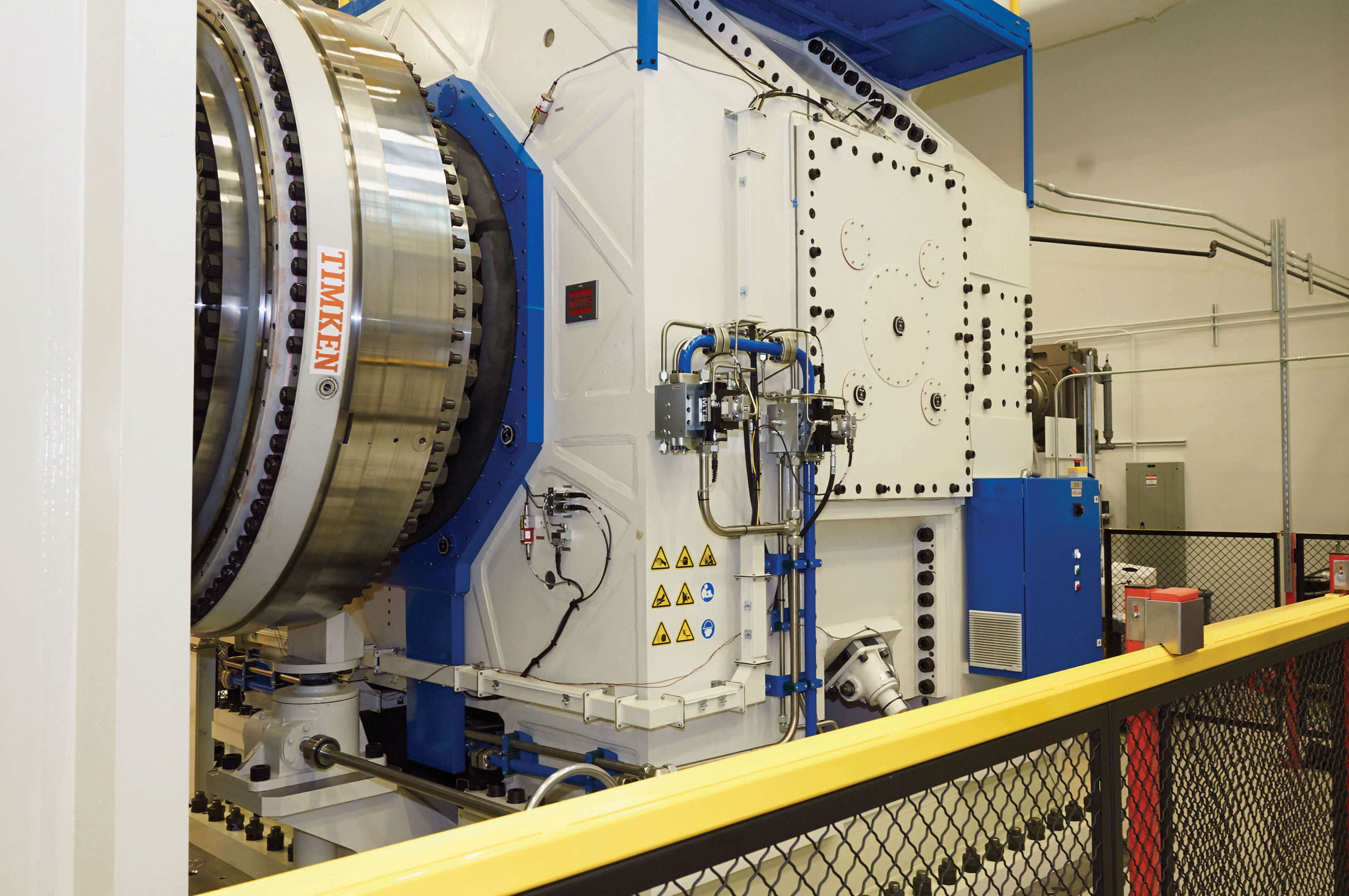

Precision machine components are intricately engineere parts that are manufacture with utmost accuracy using advance machining techniques. These components play a vital role in the operation and performance of various machines, including wind turbines. The design and manufacturing process of these components are carrie out with meticulous attention to detail, ensuring high precision and tight tolerances, which results in enhanced efficiency and reliability.

Step 1: How do Precision Machined Components Improve Wind Energy Efficiency?

- Enhanced Aerodynamics: Precision machine components for wind turbines are crafte to provide optimal aerodynamics. Components like turbine blades and hub assemblies are designe with smooth surfaces and precise contours to minimize drag and maximize energy capture from the wind.

- Reduced Friction and Wear: Wind turbines operate in harsh environmental conditions, including strong winds and abrasive particles. Precision machining ensures the production of components with reduced friction and wear, leading to prolonged service life and decreased maintenance requirements.

- Tight Tolerances for Optimal Performance: Wind turbines rely on the harmonious interaction of numerous components. Precision machining guarantees tight tolerances and dimensional accuracy, ensuring seamless integration and smooth operation within the entire turbine system.

- Lightweight yet Durable: Precision machined components are engineere to be lightweight without compromising on strength and durability. This lightweight design reduces inertia and allows wind turbines to respond quickly to varying wind speeds, thus increasing overall energy output.

- Noise Reduction: Wind turbine noise can be a concern for both nearby communities and wildlife. Precision machining helps in crafting components that contribute to noise reduction, making wind energy installations more socially and environmentally acceptable.

Step 2: Importance of Anchored Hyperlinks

Incorporating anchored hyperlinks within the text provides readers with easy access to additional information. Here is an already anchore hyperlink to an article about precision machined components for wind

Step 3: Conclusion

Precision machined components are a vital aspect of optimizing wind energy efficiency. With their superior aerodynamics, reduced friction, tight tolerances, and noise reduction capabilities, these components contribute significantly to the overall performance of wind turbines. By embracing precision machining in wind energy production, we can foster a cleaner and more sustainable future, making wind power a reliable and environmentally friendly solution for our growing energy needs.

In conclusion, the precision machining industry’s innovations will continue to play a pivotal role in revolutionizing the wind energy sector, driving further advancements in renewable energy and contributing to a greener world.

You may also like

-

Best Phone Shop Bedford for All Your Repair Needs

-

Your Website and the AI Era: Why Proactive Maintenance is More Critical Than Ever

-

How MSP Proactive Maintenance Increases Profit Margins by 15-25%

-

Best Hotel Management Software in India

-

Enjoy the Best IPTV Indian Channel Experience: Watch India IPTV Channels Anytime