Slip rings play a crucial role in various electrical and mechanical applications, allowing the transmission of power, signals, and data between stationary and rotating parts. Whether you’re an engineer, a hobbyist, or a curious individual, understanding how to use a slip ring is essential. In this article, we will delve into the intricacies of slip rings, exploring their applications, installation, maintenance, and troubleshooting techniques. So, let’s dive in and unlock the secrets of using a slip ring effectively!

How to Use a Slip Ring: The Basics

What is a Slip Ring?

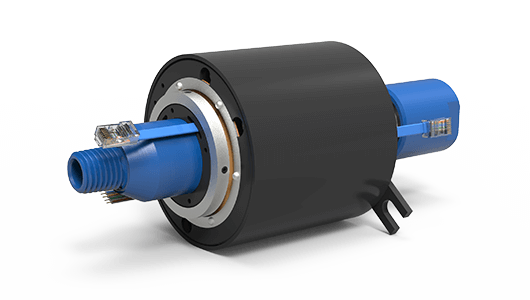

A slip ring, also known as a rotary electrical joint or collector ring, is an electromechanical device that facilitates the transmission of electrical power, signals, or data from a stationary structure to a rotating one. It allows continuous rotation without tangling or twisting cables, ensuring seamless communication and functionality.

Understanding the Working Principle

A slip ring consists of two primary components: a stationary part, known as the stator, and a rotating part, called the rotor. The stator is typically connected to the stationary structure, while the rotor is connected to the rotating component. Within the slip ring assembly, conductive rings and brushes enable the transfer of electricity, signals, or data.

When the rotor rotates, the brushes maintain contact with the rings, ensuring a continuous flow of current or signals. This enables the seamless transmission of power or information, making slip rings essential in applications where continuous rotation is required.

Installing a Slip Ring: Step-by-Step Guide

Step 1: Gather the Required Tools and Equipment

Before installing a slip ring, make sure you have the necessary tools and equipment. These may include a screwdriver, pliers, electrical tape, wire strippers, and, of course, the slip ring itself. Refer to the manufacturer’s instructions to ensure you have all the components needed for a successful installation.

Step 2: Identify the Mounting Location

Determine the ideal location for mounting the slip ring. Consider factors such as accessibility, proximity to the rotating part, and the length of cables required for connection. Ensure that the chosen location provides sufficient clearance and does not interfere with other components or structures.

Step 3: Prepare the Stator and Rotor Connections

Carefully connect the necessary cables to both the stator and rotor sides of the slip rings. Strip the insulation from the cable ends, ensuring a clean and exposed conductor. Use wire strippers to remove the insulation, leaving about 1/2 inch of exposed wire for secure connections.

Step 4: Mount the Slip Ring

Align the slip rings assembly with the mounting location and secure it using screws or other fastening mechanisms provided by the manufacturer. Ensure that the slip ring is firmly attached and does not wobble or move when subjected to rotational forces.

Step 5: Test the Connections

Once the slip ring is securely mounted, test the connections to ensure proper functionality. Use a multimeter or other suitable testing equipment to check for continuity and verify that the electrical signals or power can flow seamlessly through the slip rings.

Step 6: Insulate and Protect the Connections

After testing the connections, insulate them using electrical tape or heat-shrink tubing. This step prevents short circuits, protects against moisture or dust ingress, and ensures the longevity of the slip rings assembly.

Maintenance Tips for Long-Term Reliability

Regular Inspection

Periodically inspect the slip rings assembly for any signs of wear, damage, or contamination. Look for loose connections, broken wires, or excessive brush wear. Identifying issues early on can help prevent costly repairs or unexpected failures.

Cleaning the Slip Rings

Clean the slip rings regularly to remove dirt, dust, or debris that may accumulate over time. Use a lint-free cloth or a mild solvent to gently clean the rings and brushes. Avoid using abrasive materials that could damage the slip ring’s surface.

Lubrication

Some slip rings require periodic lubrication to ensure smooth rotation and reduce friction. Check the manufacturer’s instructions to determine the type of lubricant suitable for your slip rings. Apply the lubricant sparingly and avoid over-lubrication, as it may attract more dirt or interfere with electrical conductivity.

Conclusion

Slip rings are versatile devices that facilitate the transmission of power, signals, or data between stationary and rotating parts. Understanding how to use a slip ring is essential for engineers, hobbyists, and individuals working with rotating systems. By following the installation guidelines, performing regular maintenance, and selecting the appropriate slip ring for your application, you can ensure optimal performance, reliability, and longevity.

You may also like

-

Best Phone Shop Bedford for All Your Repair Needs

-

Your Website and the AI Era: Why Proactive Maintenance is More Critical Than Ever

-

How MSP Proactive Maintenance Increases Profit Margins by 15-25%

-

Best Hotel Management Software in India

-

Enjoy the Best IPTV Indian Channel Experience: Watch India IPTV Channels Anytime