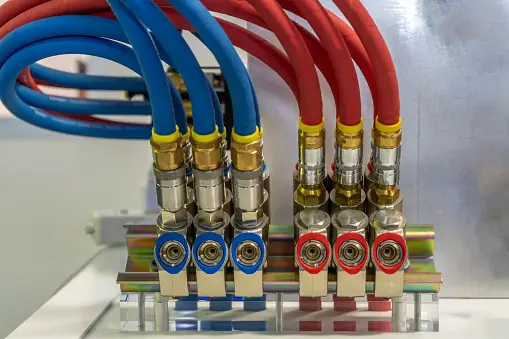

Teflon hoses are the go-to choice for various industrial applications due to their exceptional performance and reliability. These hoses, made from polytetrafluoroethylene (PTFE) or Teflon, offer unique qualities that set them apart. With unrivalled chemical resistance and the ability to withstand high temperatures, Teflon hoses ensure seamless fluid transfer, making them indispensable in chemical processing, food and beverage, pharmaceuticals, and other industries. This blog will explore why Teflon hoses have become the preferred solution for industrial applications, highlighting their remarkable attributes and benefits.

Unparalleled Chemical Resistance

Teflon hose manufacturers are well-known for their exceptional chemical resistance, which makes them the best choice for industrial applications. These hoses are made of PTFE, a synthetic polymer that can withstand exposure to various chemicals without damage. Unlike other materials, such as rubber, which can get corroded or degraded when exposed to harsh chemicals, PTFE is inert and does not react with the substances it comes into contact with. This makes Teflon hose manufacturers provide adequate hoses that will be ideal for transporting corrosive or abrasive chemicals such as acids, solvents, and alkalis.

Another advantage that Teflon hoses offer is that they do not absorb the chemicals they transport, which can be a common problem with other materials. When chemicals are absorbed into the hose material, it can cause contamination, which can be dangerous in certain industries such as food and beverage, pharmaceuticals, and biotech. Teflon hoses prevent this from happening, ensuring that the chemicals remain pure and uncontaminated during transport.

In addition to their chemical resistance, Teflon hoses are also resistant to high pressure and temperature, making them suitable for use in extreme environments. They can handle operating pressures of up to 5,000 psi and temperatures of up to 500°F without getting damaged or deformed. This makes them a reliable choice for industrial applications where high pressure and temperature are common.

High-Temperature Endurance

Teflon hoses are known for their ability to withstand high temperatures, making them ideal for high-temperature environments. PTFE has a high melting point of around 620°F, which means it can handle temperatures that cause other materials to melt or deform. This makes Teflon Hoses the go-to choice for aerospace, automotive, and oil and gas industries, where high-temperature conditions are common.

In addition to their high-temperature endurance, Teflon hoses also offer excellent thermal stability, which means they can maintain their properties even when exposed to extreme temperature fluctuations. This makes them suitable for applications where temperature changes occur frequently, such as in chemical processing or semiconductor manufacturing.

Versatility in Industrial Applications

Teflon hoses are versatile and can be used in various industrial applications. They are commonly used in chemical processing for transporting corrosive chemicals, acids, and alkalis. They are also used in the food and beverage industry for transporting food-grade materials such as milk, juice, and beer. Teflon hoses transport medical-grade materials such as vaccines, drugs, and other pharmaceutical products in the pharmaceutical industry.

Another area where Teflon hoses are commonly used is in the automotive industry. Thanks to their chemical resistance and durability, they are used for transporting fuel, oil, and brake fluid. The aerospace industry also uses Teflon hoses for transporting hydraulic fluids, fuel, and other chemicals.

Enhanced Durability and Longevity

Teflon hoses are highly durable and can last long, even in harsh environments. PTFE is a tough material that can withstand abrasion, impact, and chemical exposure without getting damaged. This means Teflon hoses can be used for extended periods without replacement, reducing downtime and maintenance costs.

Another advantage of Teflon hoses is that they are resistant to ageing, which means they do not degrade over time, even when exposed to harsh environmental conditions such as sunlight and extreme temperatures. This makes them a reliable choice for industrial applications where longevity and durability are important factors.

Flexibility and Easy Installation

Teflon hoses are flexible and easy to install, making them a popular choice for industries where ease of use is important. They can be bent and twisted without damage, so they can be easily routed around obstacles and installed in tight spaces. This makes them ideal for use in applications where space is limited, such as in automotive and aerospace.

Another advantage of Teflon hoses is that they are lightweight, which makes them easy to handle and manoeuvre during installation. They can be cut to the desired length and fitted with the appropriate fittings, making them easy to customise for specific applications.

Conclusion

Teflon hoses have become the preferred solution for industrial applications due to their exceptional performance and reliability. With their unparalleled chemical resistance, high-temperature endurance, versatility, enhanced durability and longevity, flexibility and easy installation, Teflon hoses offer a range of benefits that make them ideal for use in a wide range of industries. Whether you are in the chemical processing, food and beverage, pharmaceutical, automotive, or aerospace industry, Teflon hoses offer a reliable and efficient way to transport fluids, ensuring seamless operations and productivity.

You may also like

-

Automatic Fruit Wine Bottling Line for Small Wineries: A Complete Guide

-

How Does Plywood HSN Code Decide the GST Rate for Traders and Manufacturers?

-

POS Terminal Type: Which Is Best for Your Business?

-

How to Choose Fixed and Portable Gas Monitors for Industrial Gas Detection?

-

Simplifying Trademark Registration in Hong Kong: What Businesses Need to Know