Advancements in Medical Devices through Precision Machining

The healthcare industry is constantly evolving, and one of the key drivers of this evolution is precision machined parts. These intricate components play a pivotal role in the development of cutting-edge medical devices and equipment. In this article, we will explore how precision machined parts are revolutionizing healthcare and contributing to the improvement of patient care and medical technology.

What are Precision Machined Parts?

Precision machined parts are highly specialize components that are manufacture with the utmost accuracy and precision. These parts are typically produce using advanced machining techniques such as CNC (Computer Numerical Control) machining, milling, and turning. The materials used for these parts can vary widely, from metals like titanium and stainless steel to plastics and ceramics.

Applications in Medical Devices

- Surgical Instruments: Precision machined parts are essential in the manufacturing of surgical instruments. These instruments require precision machined parts for healthcare and reliability to ensure the safety and success of surgical procedures. Components like scalpel handles, forceps, and needle holders are often made with precision machining to guarantee their accuracy and durability.

- Imaging Equipment: Medical imaging is a critical aspect of healthcare, and precision machined parts are used in devices like MRI machines, CT scanners, and X-ray machines. These parts help maintain the integrity of these machines, ensuring high-quality imaging and accurate diagnosis.

- Implantable Devices: Precision machined parts are use in the production of implantable devices such as pacemakers, artificial joints, and dental implants. These components must be biocompatible and durable to withstand the harsh conditions inside the human body while providing optimal performance.

- Drug Delivery Systems: Precision machining plays a crucial role in the development of drug delivery systems, including insulin pumps and inhalers. These devices must be reliable and precise to deliver medication accurately to patients.

Advantages of Precision Machined Parts in Healthcare

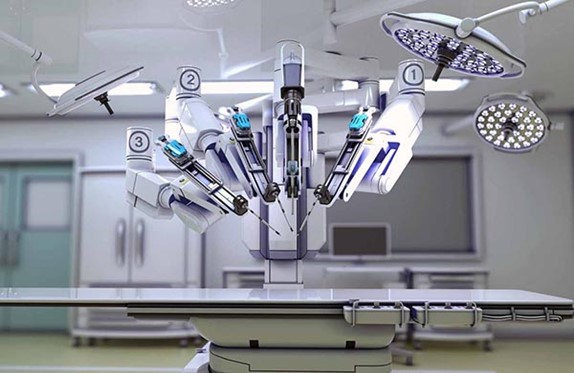

- High Precision: Precision machining offers unparalleled accuracy, ensuring that medical devices function reliably and consistently. This precision is critical in applications like robotic surgery and implantable devices.

- Customization: Healthcare is not one-size-fits-all, and precision machining allows for the customization of medical devices to meet individual patient needs. Customized components can improve patient outcomes and comfort.

- Durability: Medical devices must withstand harsh conditions, such as sterilization processes and exposure to bodily fluids. Precision machine parts are designe to be durable and resistant to corrosion, extending the lifespan of medical equipment.

- Reduced Risk: Precision machining minimizes the risk of human error in manufacturing, which is crucial in healthcare to prevent accidents or device failures during medical procedures.

- Miniaturization: As technology advances, the trend in healthcare is towards smaller, more minimally invasive devices. Precision machining enables the production of tiny, intricate components that are vital for the development of such devices.

Challenges and Future Prospects

While precision machining has transformed healthcare in many ways, it is not without its challenges. Tight regulations, the need for specialize expertise, and the high cost of machining equipment are some of the obstacles face by manufacturers in this field. However, ongoing advancements in technology and materials are continuously pushing the boundaries of what is possible in precision machining.

In the future, we can expect even greater miniaturization, increased use of biocompatible materials, and improved efficiency in the production of precision machined parts for healthcare. These developments will lead to more innovative medical devices, improved patient care, and further advancements in medical technology.

Conclusion

Precision machined parts have become the unsung heroes of the healthcare industry, contributing to the development of life-saving medical devices and equipment. Their precision, durability, and customization capabilities make them invaluable in an industry where accuracy and reliability are paramount. As technology continues to advance, the role of precision machining in healthcare is only expecte to grow, leading to improved patient outcomes and a brighter future for medical technology.

You may also like

-

Effortless Pigmentation Mark Removal: Exploring the Benefits of Yellow Laser Treatment

-

Pelvic Mesh Implants: What You Should Know About Potential Side Effects

-

How to Recover From a Foot Injury

-

Finding Balance: 7 Stores Offering the Best Traditional Chinese Medicine for Stress Relief

-

Sildisoft 100 and Valentine’s: Crafting Moments of Love