In the realm of electronic manufacturing, understanding the cost intricacies of Printed Circuit Board Assemblies (PCBA) is crucial. The process involves various components, steps, and considerations, making it a pivotal aspect of product development. Delving into the essence of PCBA, it’s essential to know what’s the difference between PCB and PCBA.

PCB vs. PCBA: Unveiling the Distinction

Printed Circuit Board (PCB) stands as the core foundation of electronic circuits. It’s a physical board composed of conductive and non-conductive materials. Copper trades on the board form a network to connect various electronic components, facilitating the flow of electricity.

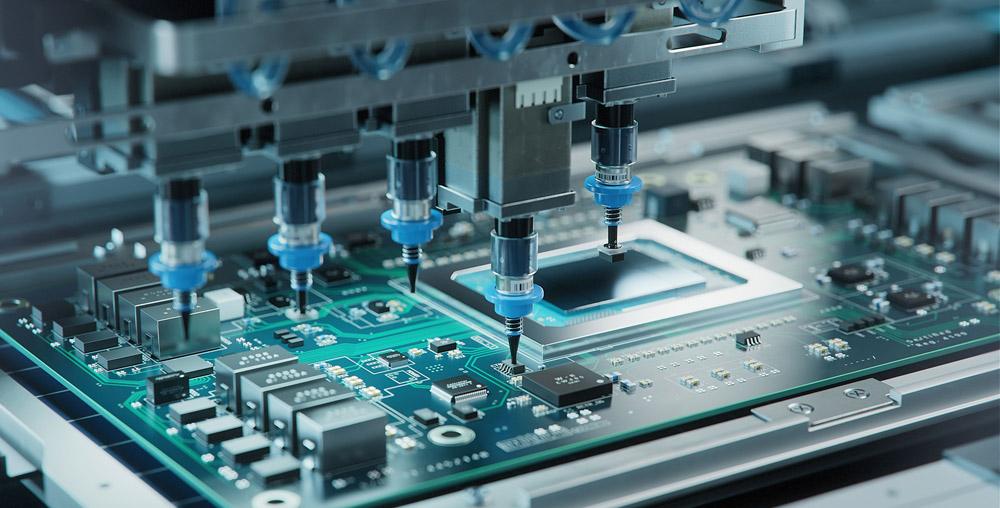

Printed Circuit Board Assembly (PCBA), on the other hand, involves the process of mounting electronic components onto the bare PCB. These components can range from resistors, capacitors, and integrated circuits to more intricate parts. The PCBA process transforms a bare PCB into a functional electronic device.

Factors Influencing PCBA Cost

Calculating the price of PCBA assembly involves multifaceted considerations. From the intricacy of the design to the types of components used, several factors influence the final cost.

PCB Production Cost:

PCB Material: The choice of materials—ranging from single-sided to multi-layered PCBs—impacts costs. Variations in materials, thickness, and copper content contribute to price differences.

Manufacturing Process: Different production techniques, such as gold-plating or tin-spraying, affect costs. Advanced processes can increase prices due to intricate manufacturing requirements.

PCB Complexity: Varied specifications like hole diameters, line widths, and intricate designs contribute to the complexity, directly impacting costs.

Component Purchase Cost:

Component Sourcing: The cost of sourcing components constitutes a significant portion of PCBA. Bulk purchases or specialized components can influence overall expenses.

SMT (Surface Mount Technology) Processing Cost:

SMT Technology: The intricacy and volume of SMT placements, including fine pitch components like BGAs and QFNs, contribute to costs. Each placement type is associated with specific pricing.

Assembly Testing Cost:

Testing Requirements: Comprehensive testing, including assembly testing and packaging, adds to the overall expense. The volume and complexity of testing directly affect costs.

Calculating PCBA Price: Detailed Breakdown

A comprehensive understanding of PCBA cost involves meticulous calculation and assessment.

Assembly Part Details: Providing specific information about the assembly, such as part numbers, service order types (kitted, consigned, or combo), and the quantity of boards to be assembled, is crucial.

Types of Placements: Distinct placement types—SMT, fine pitch, BGA/QFN/Leadless, and through-hole placements—demand accurate quantification, as each contributes differently to the final cost.

Board Specifications: Considering aspects like board types (single or panelized PCBs), assembly sides, RoHS compliance, and assembly lead time influences the pricing.

Additional Technical Information: Detailed inputs about the assembly process, such as centroid data, assembly files, layers of circuits, and BOM specifics, further refine cost estimates.

Minimizing Costs While Ensuring Quality

While understanding the factors contributing to PCB Assembly cost is crucial, striving to minimize expenses without compromising quality is equally important.

Efficient Sourcing: Opting for reputable PCB assembly services and efficient component sourcing strategies can reduce overall expenses.

Optimized Design: Streamlining PCB designs, choosing cost-effective materials, and focusing on efficiency during assembly contribute to cost reduction.

Bulk Orders: Leveraging economies of scale by placing larger orders can lead to reduce per-unit assembly costs.

In essence, comprehending the complexities of PCBA cost calculation empowers manufacturers to make informed decisions, ensuring cost efficiency without compromising the quality and functionality of the final product.

FAQS (Frequently Asked Questions):

What is the primary difference between PCB and PCBA?

PCB refers to a bare printed circuit board, whereas PCBA involves the assembly of electronic components onto the PCB.

What factors influence the cost of PCBA assembly?

Several factors, including PCB material, manufacturing process, component sourcing, SMT technology, testing requirements, and board specifications, impact the overall cost.

How does PCB complexity affect assembly costs?

Complex designs with intricate specifications, such as varied hole diameters or line widths, can increase the cost due to higher manufacturing complexities.

What role does SMT technology play in determining the assembly cost?

Different types of SMT placements, including fine pitch components like BGAs and QFNs, contribute differently to the overall cost due to their varying complexities.

Can bulk purchasing of components reduce PCBA costs?

Yes, bulk orders often lead to economies of scale, reducing per-unit assembly costs due to reduced component pricing.

What is the significance of PCB material in cost calculation?

The choice of materials, from single-sided to multi-layered PCBs, impacts costs significantly due to variations in material quality and manufacturing requirements.

How does the assembly lead time influence PCBA pricing?

Shorter lead times might incur higher costs due to expedited processing, while longer lead times may offer cost advantages.

Are there cost differences between single-sided and panelized PCBs?

Panelized PCBs generally have higher initial costs but can be more cost-effective in larger quantities due to higher production efficiency.

What strategies can help minimize PCBA costs without compromising quality?

Efficient component sourcing, optimized PCB designs, and placing bulk orders are effective strategies to reduce costs while ensuring high-quality assembly.

Is testing an additional cost in PCBA assembly?

Yes, comprehensive testing, including assembly testing and packaging, incurs additional costs, usually based on the volume and complexity of testing required.

How does the RoHS compliance choice affect PCBA pricing?

Opting for lead-free RoHS-compliant processes might marginally increase costs due to the use of specific materials and processing methods.

Can specific board specifications significantly impact assembly costs?

Yes, board specifications like assembly sides, surface mount components, and through-hole placements can influence costs depending on complexity and quantity.

Is there a difference in pricing for fine pitch and standard SMT components?

Yes, fine pitch components (such as BGAs or QFNs) often incur higher costs due to their intricate nature and specialized assembly requirements.

Do different assembly service order types affect pricing?

Yes, variations in assembly service order types (kitted, consigned, or combo) may impact costs based on the sourcing and handling of components.

What additional technical information aids in accurate cost estimation?

Details like centroid data, assembly files, circuit layers, and BOM specifics offer a more comprehensive view, aiding in precise cost estimates for PCBA.

Conclusion:

In essence, comprehending the complexities of PCBA cost calculation empowers manufacturers to make informed decisions, ensuring cost efficiency without compromising the quality and functionality of the final product.

You may also like

-

Latest Technology: Why Are Mobile Games Changing the Way We Interact with the Digital World?

-

The Evolution of Storytelling in Video Games: From Pixels to Immersive Narratives

-

10 List of the Cheapest and Best Curved Type PC Monitors in 2024

-

The Role of Regulation Technology (RegTech) in Monitoring Online Color Prediction

-

How to Navigate Google Maps Transit Directions